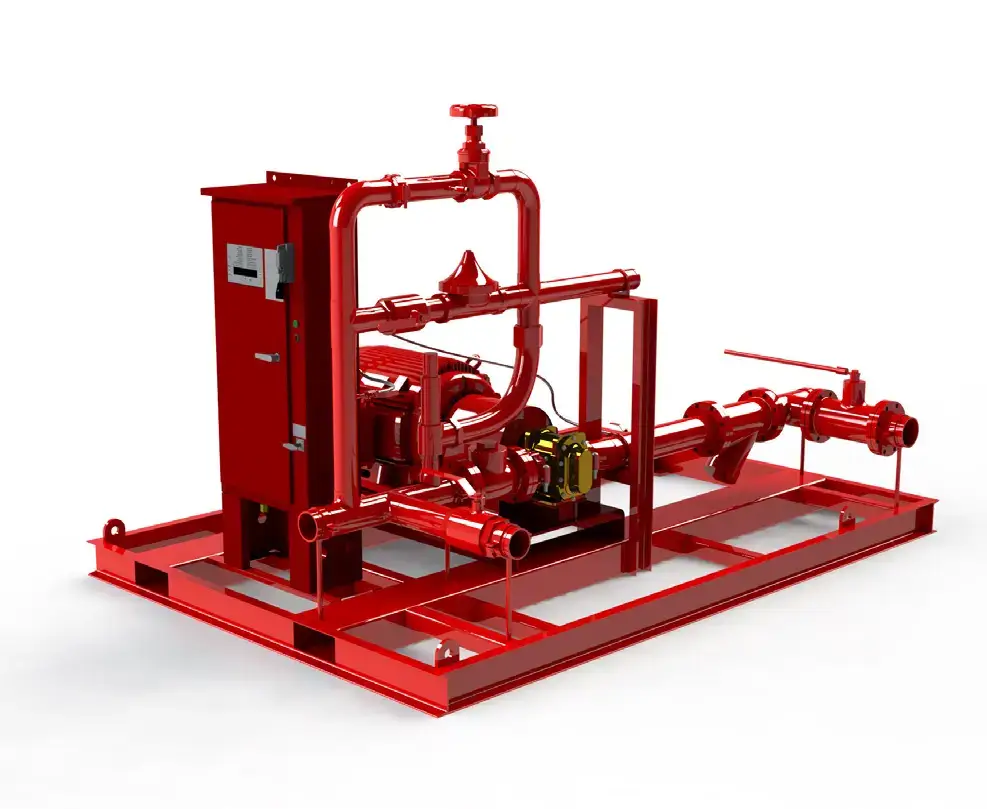

Viking FoamPak System

The Viking FoamPak foam pumping assembly is a foam concentrate delivery system incorporating UL Listed and FM Approved components. The FoamPak can supply foam concentrate to concentrate injection piping running above or below ground and over long distances.

Additionally, he Viking FoamPak is for use when a positive pressure proportioning foam system is the preferred method or when a central foam reserve with multiple remote injection points is required giving ultimate foam system flexibility.

System flexibility

The Viking FoamPak is a pre-fabricated and tested foam pumping system incorporating a foam pump, pre-wired pump controller, pressure sustaining valve and pressure relief valve.

Furthermore, the system piping is of stainless steel construction and includes the supply and discharge piping connections, auxiliary flushing connections, concentrate discharge check valve, pressure sustaining valve, pump casing relief valve and concentrate supply strainer.

Foam pump

The integrated UL Listed and FM Approved positive displacement rotary gear foam pump is capable of withstanding any of the corrosive environments or viscosities that are present with foam concentrates. It is also capable of dry operation. In addition, a 6-year foam pump manufacturer warranty is included. The foam pump and FoamPak is 100% compliant with NFPA 11 and 20 standards.

Viking FoamPak and ILBP

The Viking FoamPak can be used with the Viking model VLF Inline Balanced Pressure Proportioner (ILBP) which is UL Listed and FM Approved with numerous Viking and Fomtec branded foam concentrates.

When used with an ILBP, the FoamPak assembly accurately pumps and proportions foam concentrate into a water supply producing a foam solution for distribution to the fire protection system’s discharge devices such as monitors, grate nozzles or foam chambers.

FoamPak – Features and advantages

- Preassembled skid with UL Listed and FM Approved components = fast and low cost installation

- For single or multiple system applications

- Pump controllers 220/230 V, 380/415 V, 460/480 V, 50 Hz or 60 Hz

- Controller enclosure ratings: NEMA2, NEMA3R, NEMA4 or NEMA4X

- Motors: ODP IP54 with optional IP55 (TEFC), IP65 and EEXD ratings

- Available with a wide range of standard and optional configurations

- Pump drive options like diesel engine or water turbine available

- ILBP can optionally be pre-assembled onto skid

- Factory assembled and tested to UL, FM & NFPA 11 and 20 requirements

Typical applications

Viking FoamPak pump assemblies are a critical part of fixed foam fire suppression systems which operate in the most demanding applications such as

- petro-chemical facilities

- flammable & combustible liquid storage

- tank farms

- power plants

- military installations

- jetty loading areas

Image source: Fotolia © alhim, Fotolia © industrieblick, Fotolia © zhu difeng & Stockphotosecrets